What is EDM?

EDM stands for Electrical Discharge Machining.

Simply put, EDM is the reverse of welding. The EDM process uses electricity to remove material from a conductive metal workpiece. The electrode uses an electric spark, without ever touching the part, to remove material in the shape required. There are three forms of EDM: Wire EDM, Sinker EDM, and Small Hole EDM Drilling.

Why Choose EDM?

- The EDM process allows for complex setups that conventional machining cannot achieve.

- It creates simple or complex shapes or patterns that would be challenging to produce with conventional cutting tools.

- Hold demanding tolerances that cannot be achieved with traditional machining methods.

Sinker EDM

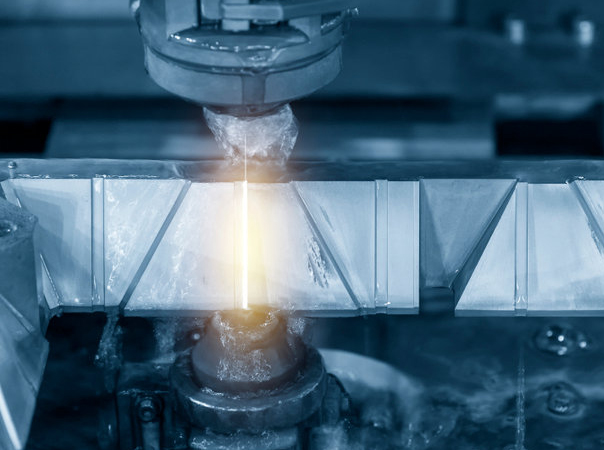

Sinker EDM is the process of eroding a shape into a workpiece, typically through the use of a graphite or copper electrode. The main dielectric fluid used is EDM oil.

Primeway Tool & Engineering has an impressive twenty-one Sinker EDM machines ready for your toughest and most complex application. Our wide range of sinkers can handle small parts as well as large parts weighing up to 20,000 lbs. Three of our sinkers also have dual heads which is especially useful for parts in the automotive die and mold industry where large molds require large cavity burns and small machining details such as reinforcing ribs. We can assist our customers throughout the full process from building the electrodes to print specifications to burning into the part.

Wire EDM

Wire EDM is the process of cutting a shape into a workpiece. The electrode used is EDM Wire which is normally comprised of brass, copper, or a multi-coated brass composition for maximizing cutting efficiency. The main dielectric fluid used is deionized water.

Primeway Tool & Engineering has five submersible Wire EDM Machines that have the capacity to hold parts up to 3,550 lbs. Our expertise and extensive knowledge allow us to cut a wide variety of shapes and sizes with extreme precision.

Small Hole EDM

Small Hole EDM Drilling is the process of drilling small diameter hole(s) into a workpiece. A brass or copper tube is normally used. Small Hole EDM Drilling can be used for a simple start hole application for the part to then be finished in a wire EDM machine, or for an application requiring thousands of holes to be drilled in a production setting. The main dielectric fluid used is deionized water.

Primeway Tool & Engineering has five Small Hole EDM Drills capable of holding parts up to 10,000 lbs. We have your complete solution for your applications that require holes as small as .008 up to .240 inches. We are capable of multiple/production hole applications, as well as tilt rotary capabilities for compound angles.